Spacer Fabric: From Next-gen Car Seat to All-purpose Programmable Textiles

2020-2023 OPT INDUSTRIES INC.

Client: Faurecia, TOPPAN, Rolls Royce

#SpacerFabric #FutureTextile #All-in-one #CustomizableCushioning #Ventilation #BreathableMaterial #Rebouncing

A New Vision for Car Seats: The Faurecia Collaboration

When Faurecia, a global leader in automotive seating, sought to develop a next-generation car seat material, the challenge was clear—traditional foam-based cushioning lacked breathability, durability, and long-term resilience. To meet the demands of comfort, ventilation, and lightweight design, we embarked on a mission at OPT Industries to create a single-material alternative that could replace complex foam layering while enhancing customization and longevity.

- Challenges in Traditional Car Seats

🚫 Foam degradation over time, leading to sagging and reduced support.

🚫 Limited breathability, causing heat buildup in long-duration seating.

🚫 Complex multi-material structures, increasing production costs and environmental impact.

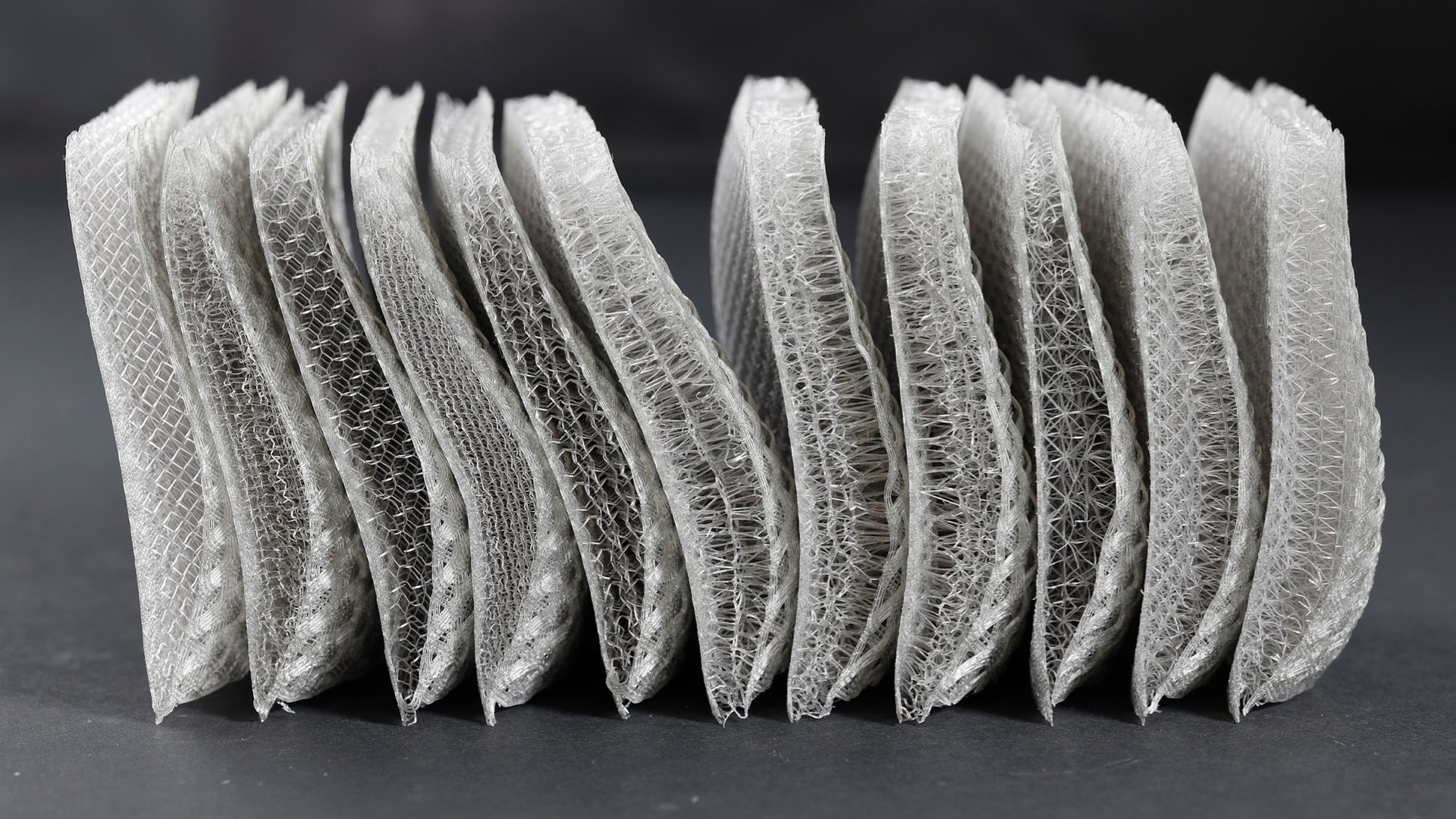

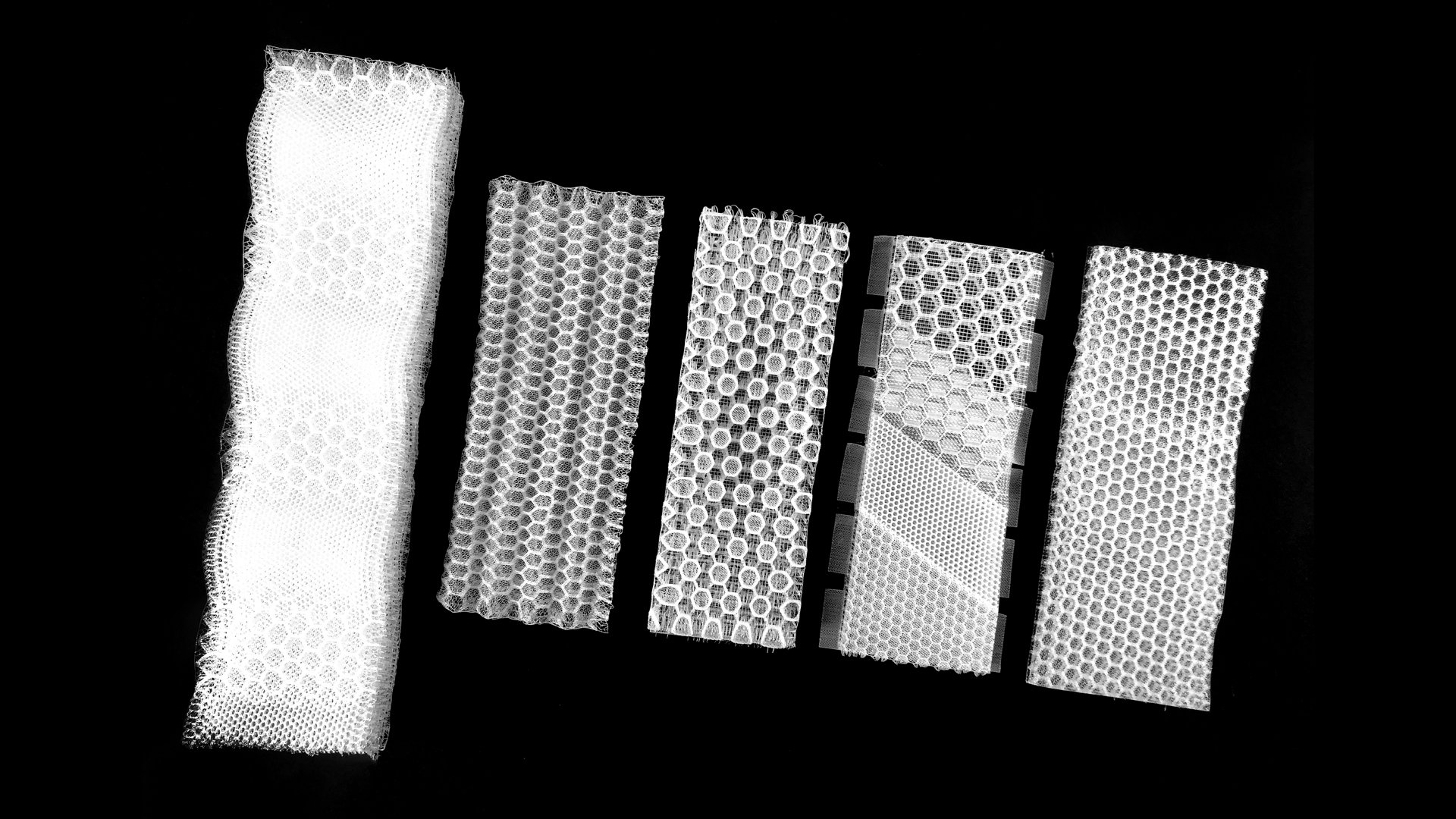

Our solution? Spacer Fabric, an engineered 3D textile that integrates cushioning, airflow, and shape retention into a single, scalable structure. The result was a programmable material that offered precision-tuned comfort, outperforming traditional foam in durability, ventilation, and customization.

Beyond Automotive: The Evolution into a Programmable Textile

As we refined Spacer Fabric for automotive seating, it became clear that its programmable nature held potential far beyond car seats. This realization led to the development of a patent-backed framework (WO2023039250A1, JP2024536742A, CN118103202A, etc.) that enabled us to design and manufacture Spacer Fabric parametrically, adapting it to various industries including medical, sportswear, and ergonomic applications.

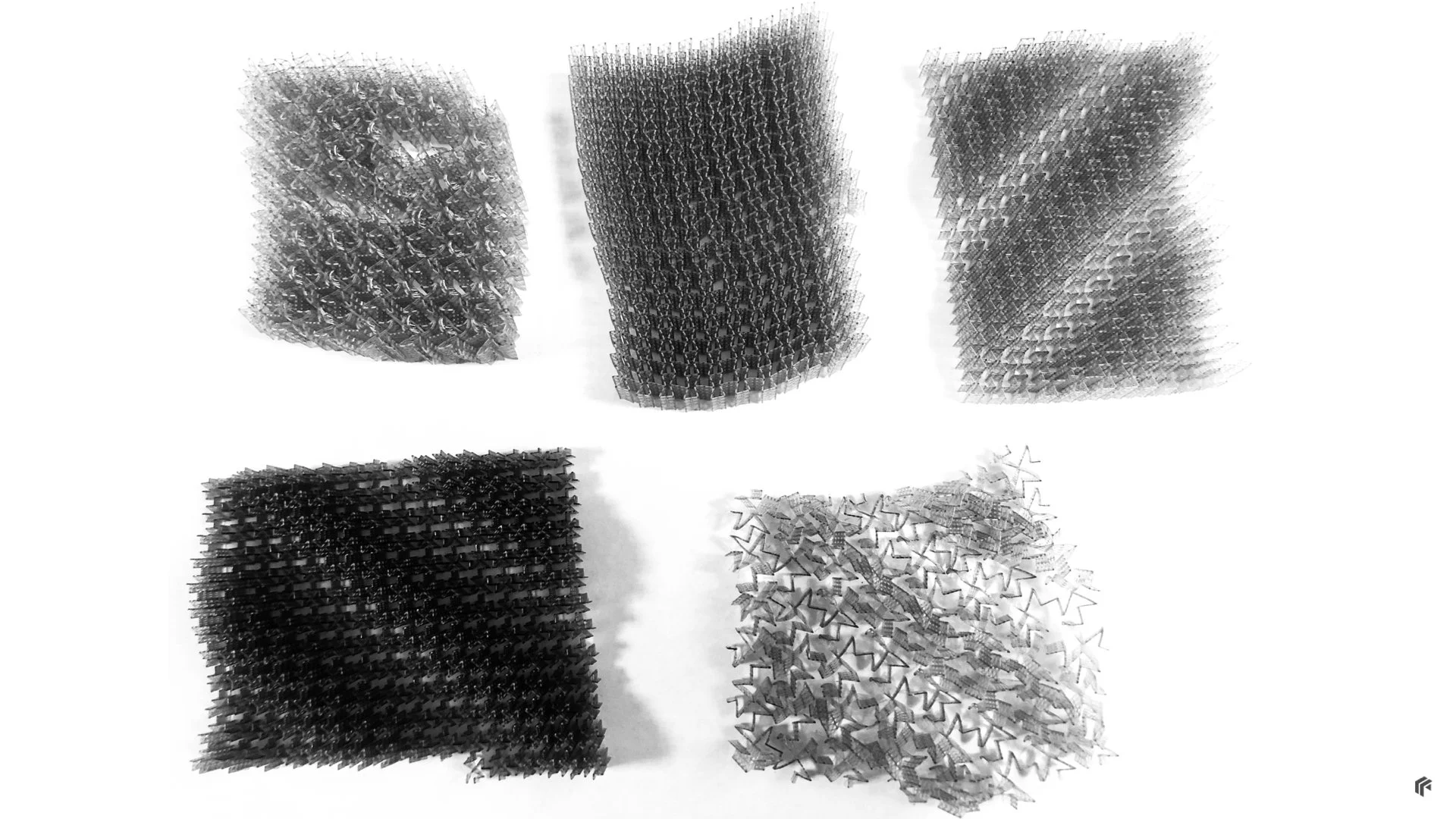

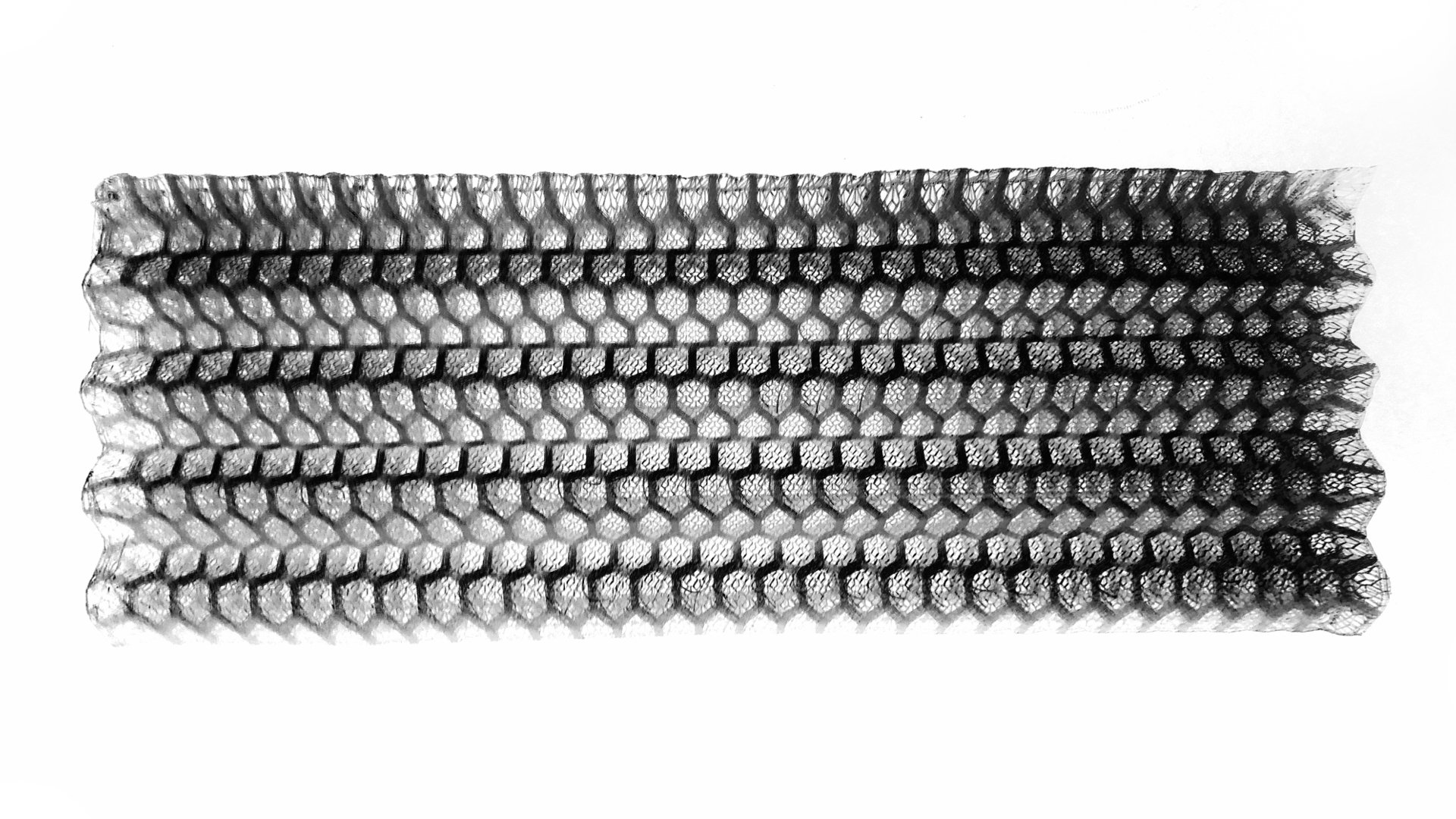

- Hierarchical Structure & Parametric Design

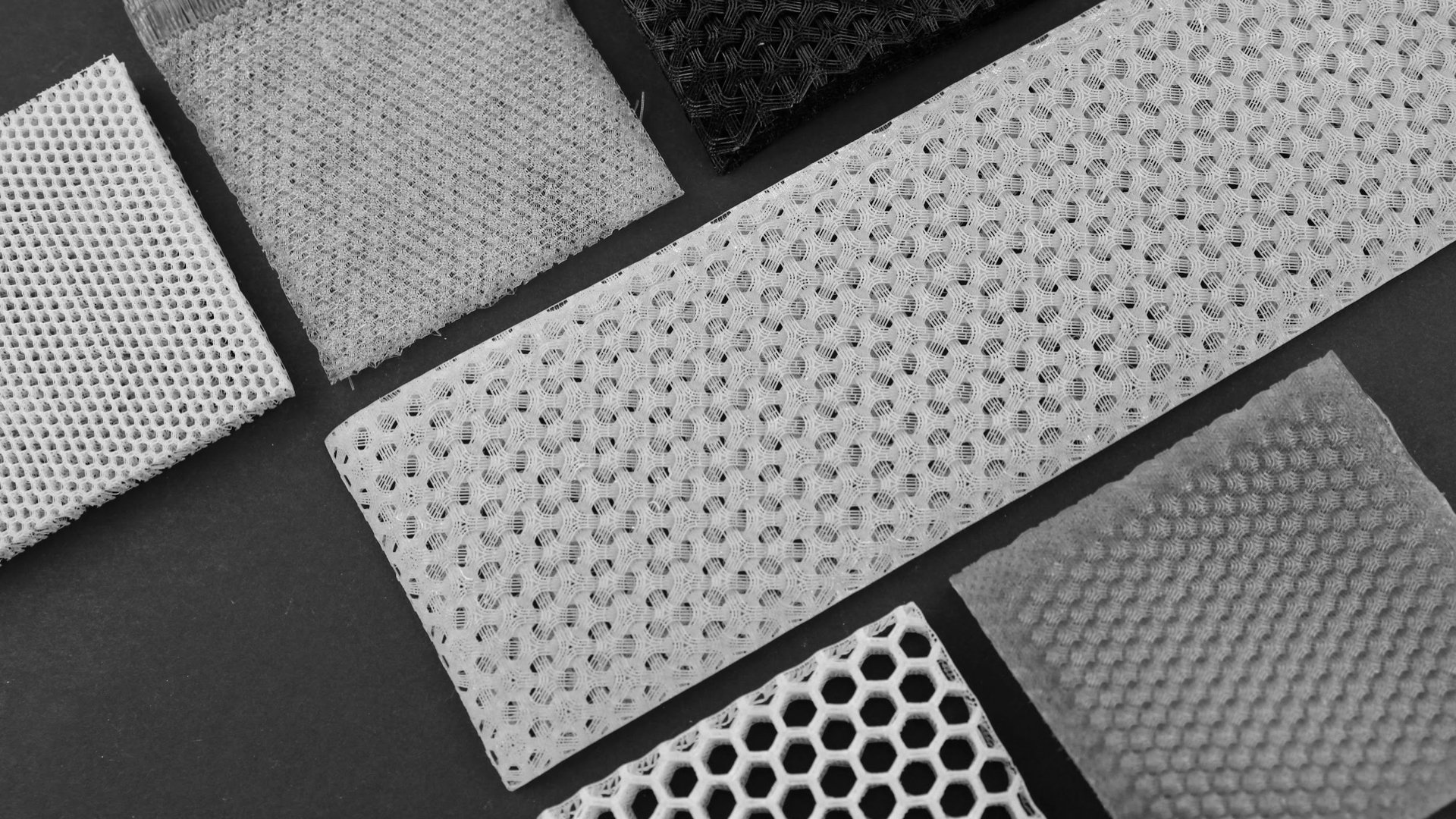

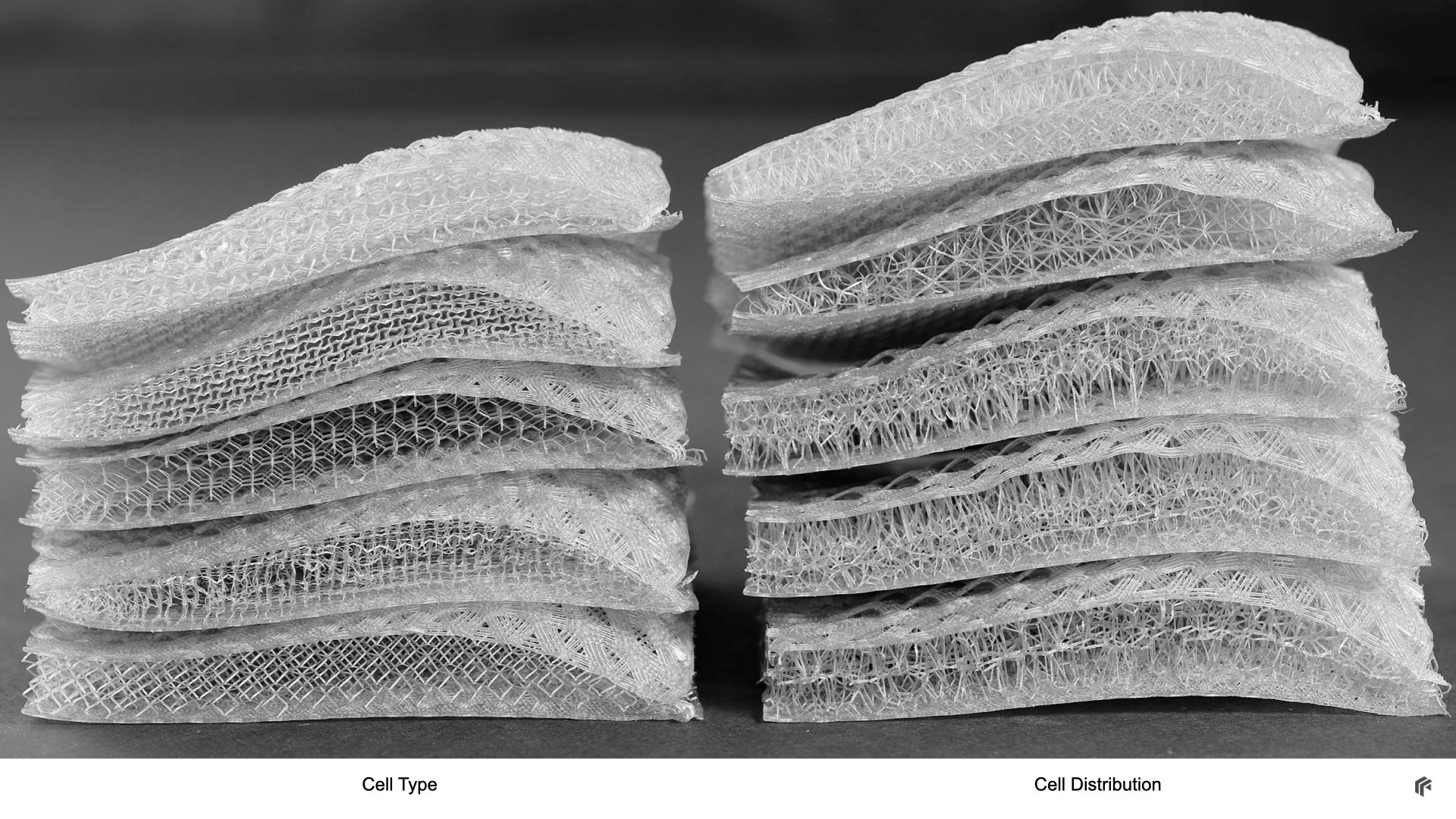

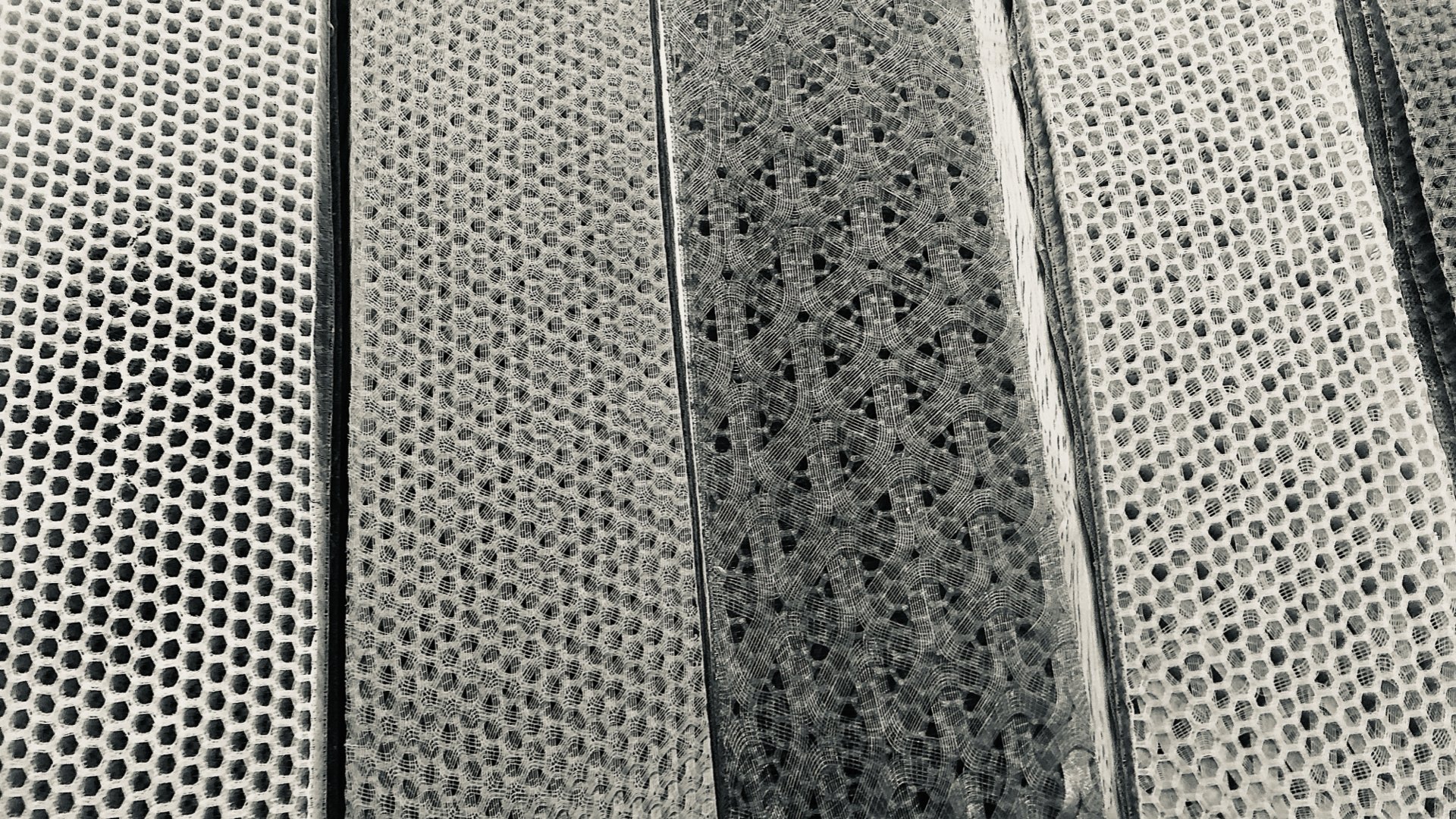

Unlike traditional textiles, Spacer Fabric is engineered rather than woven, leveraging a parametric algorithm to precisely control:

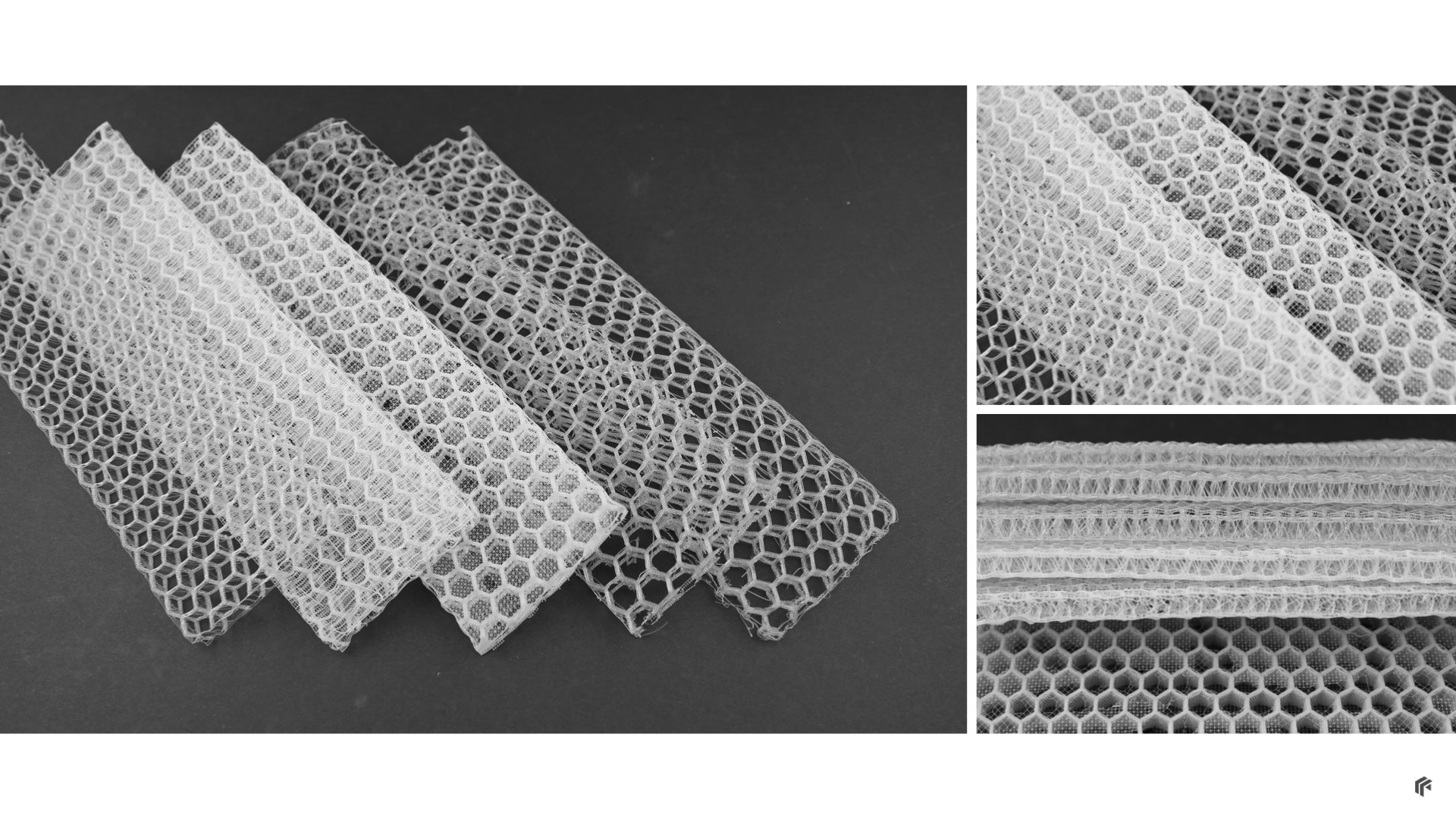

✅ Layer thickness and porosity – Optimizing breathability and load distribution.

✅ Lattice density – Adjusting stiffness and cushioning zones.

✅ Elastomeric response – Fine-tuning rebound behavior for adaptive comfort.

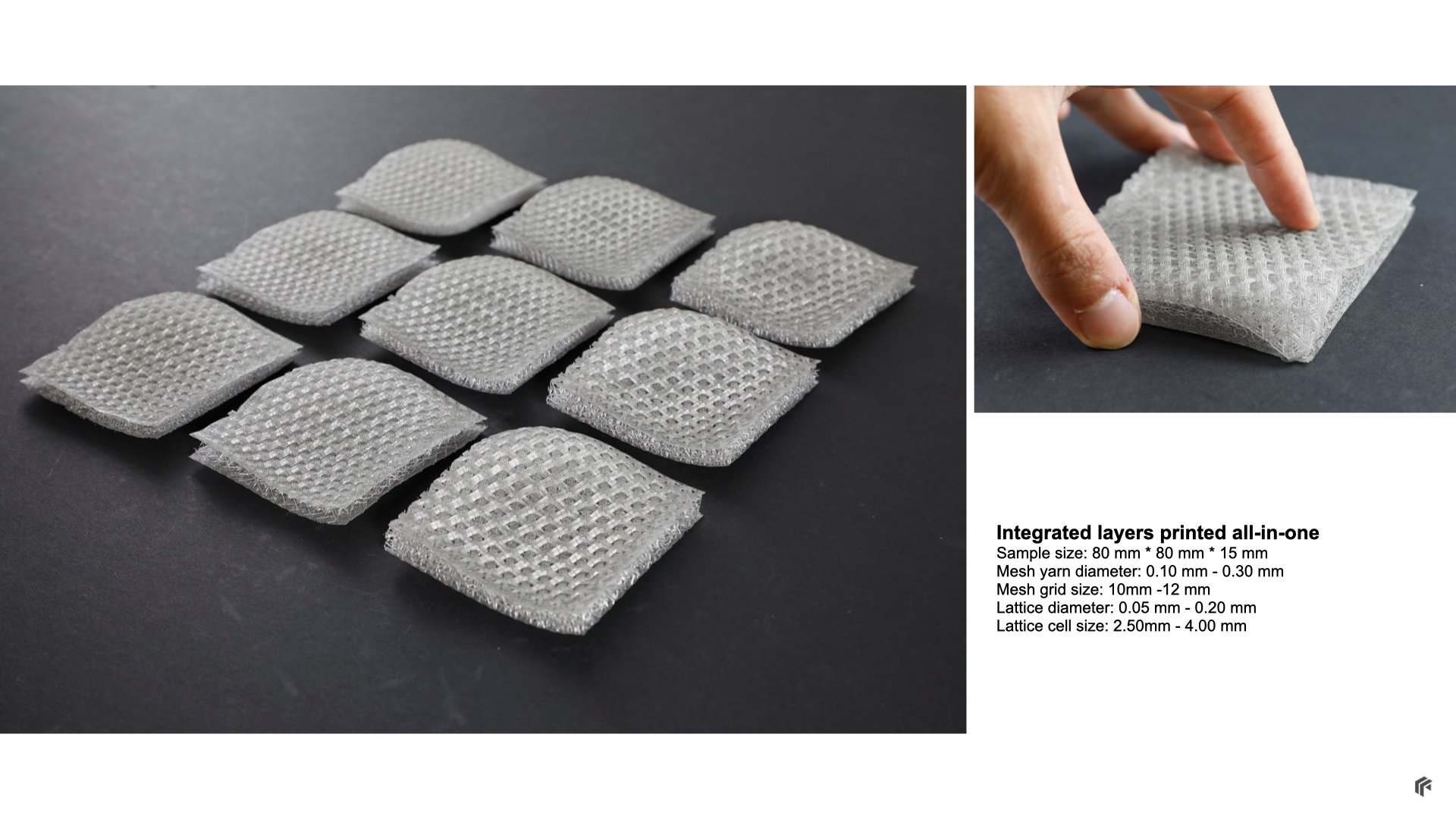

At the core of Spacer Fabric’s adaptability is a computational algorithm that automates material construction, generating customized structures based on performance requirements. This approach allows us to fine-tune the material’s mechanical properties, enabling different variations for distinct applications without requiring an entirely new production setup.

Patent-Protected Innovation: Engineering Comfort at Every Layer

The Spacer Fabric patent, which I led alongside my team at OPT Industries, details a multi-layered textile framework designed to replace foam-based cushioning while offering parametric adjustability.

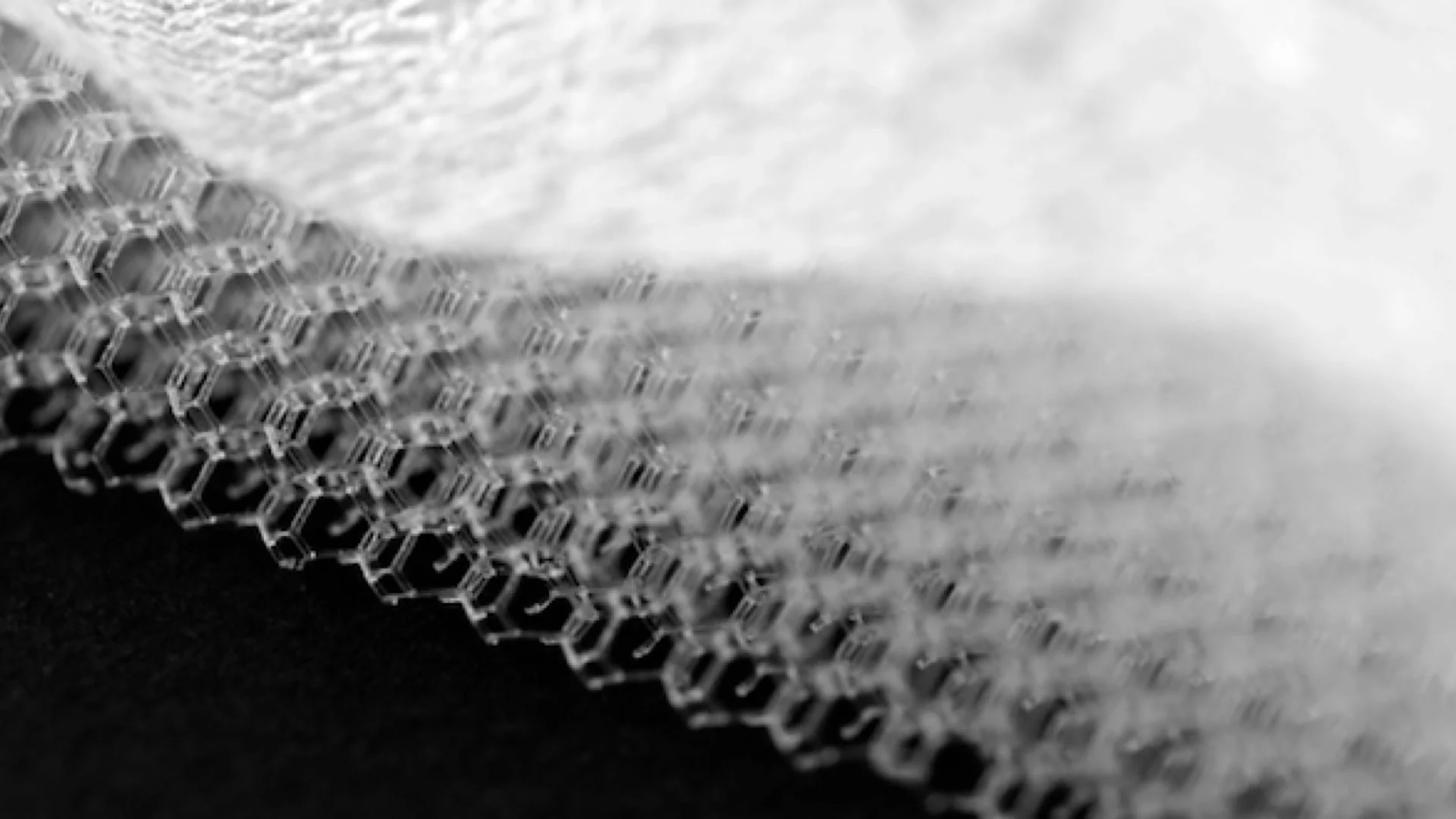

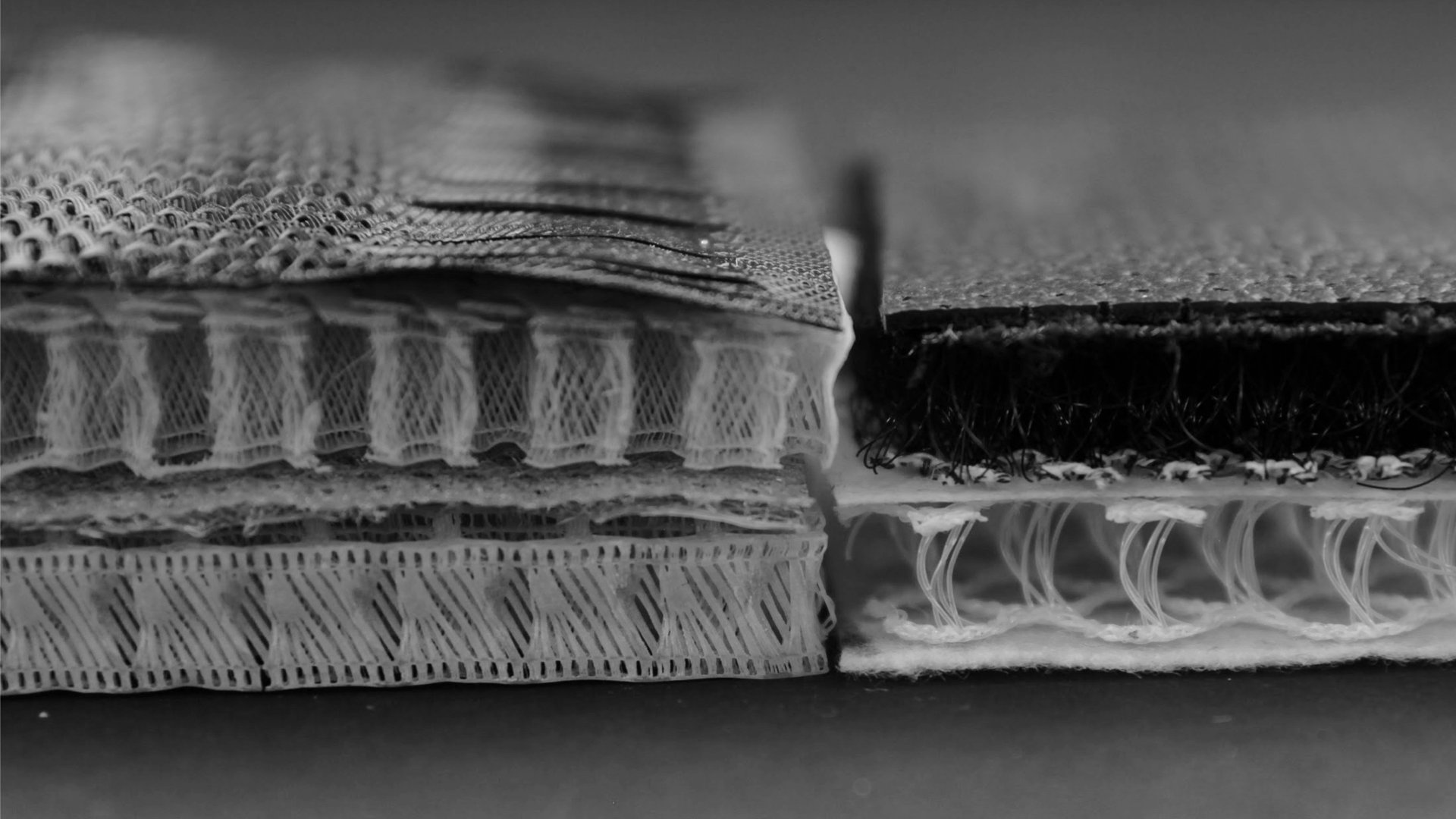

- Three-Tiered Structure:

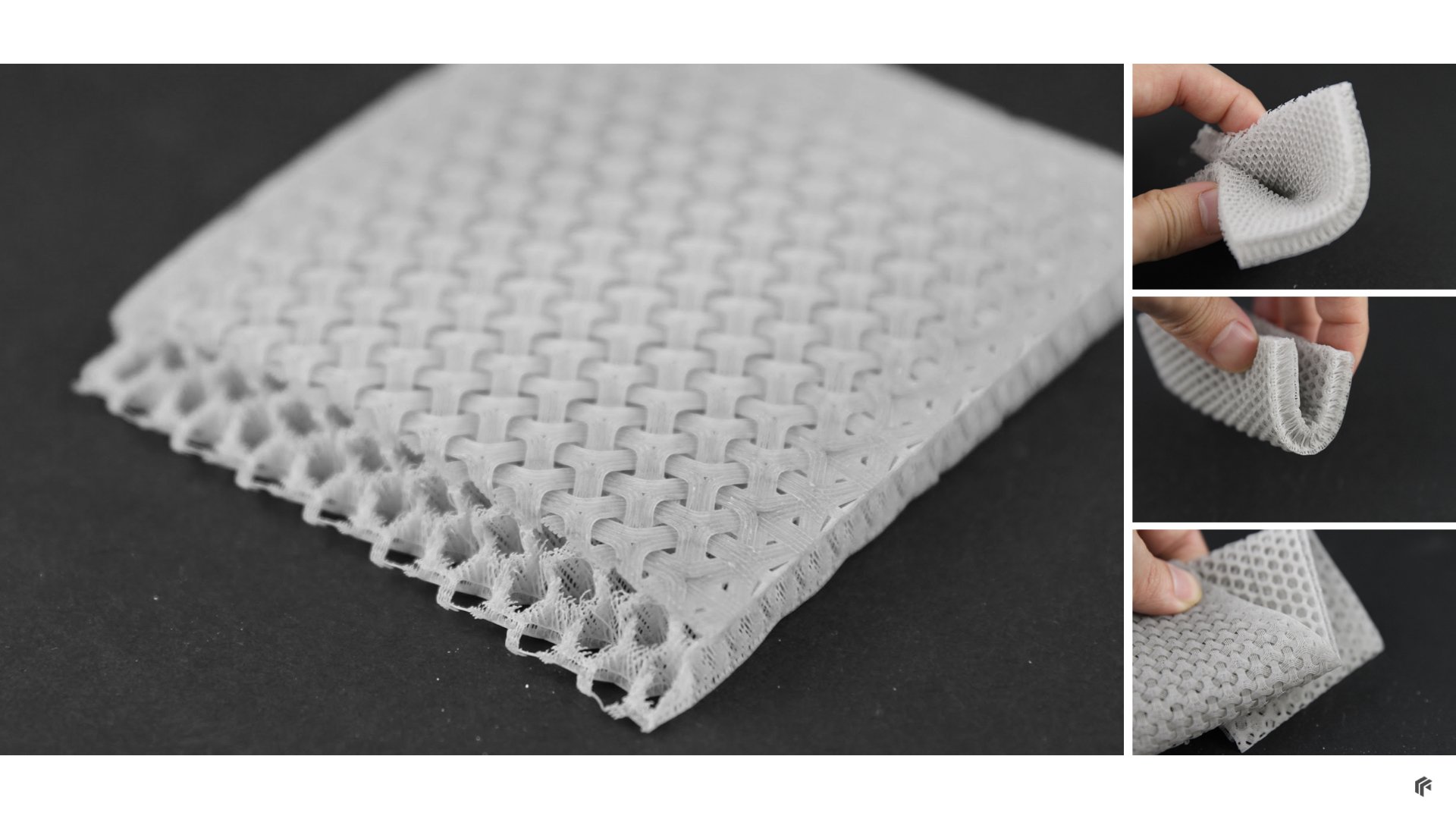

🔹 Surface Layers – Soft & Breathable

Designed with high-stretch fibers to provide skin-friendly, ventilated surfaces.

Enables improved airflow and moisture regulation, ideal for seating and wearables.

🔹 Middle Spacer Layer – Structural Cushioning

Features a programmable lattice network that adjusts compression and rebound properties.

Controls softness, density, and responsiveness based on end-use requirements.

🔹 Bottom Layer – Load Support & Stability

Engineered to prevent sagging while maintaining flexibility and durability over time.

Reduces material waste by replacing multiple foam layers with a single structure.

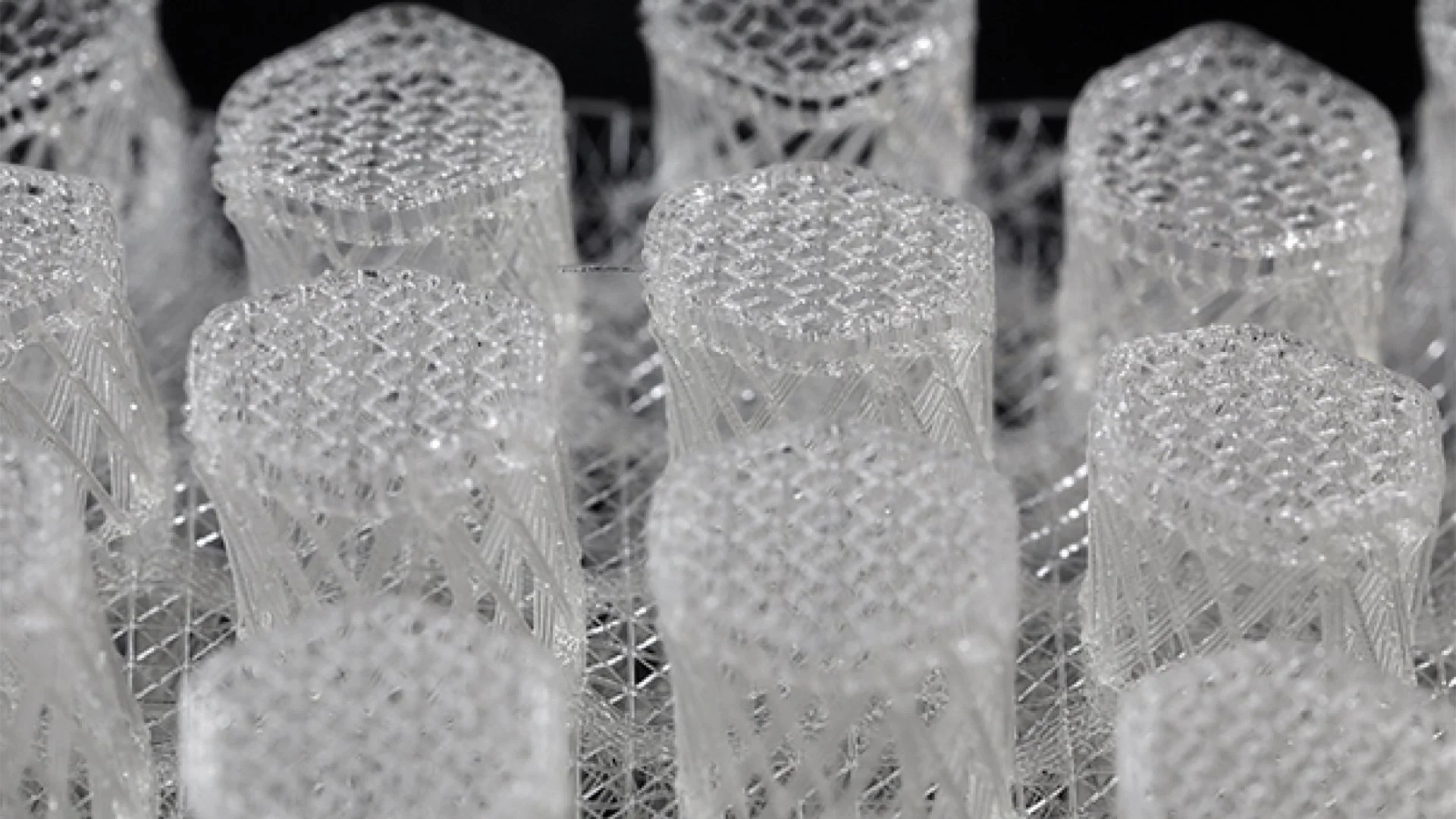

By using computational design, we were able to automate the material generation process, making Spacer Fabric infinitely scalable across industries while ensuring precision-tuned performance.

From Automotive to a Broader Spacer Fabric Series

Spacer Fabric’s programmable properties enabled its expansion into various high-performance applications:

🚗 Automotive Interiors – High-durability seating solutions for luxury and EV markets, integrating ventilation and adaptive cushioning.

🏥 Medical & Wearables – Pressure-adaptive textiles for orthopedic cushions, rehabilitation, and smart textiles.

👕 Sports & Performance Gear – Impact-resistant, breathable materials for athletic wear and protective gear.

💺 Ergonomic Seating – Long-lasting, self-adjusting chair cushions for office and industrial applications.

By leveraging parametric algorithms, each variation of Spacer Fabric is customized for specific mechanical and sensory properties, offering tailored solutions across industries.

Final Thoughts: The Future of Adaptive Textiles

The Spacer Fabric project represents a fundamental shift in textile engineering—turning fabric into a programmable system that dynamically adapts to human interaction and environmental conditions.

From automotive to smart textiles, this innovation is redefining materials by combining customization, efficiency, and sustainability into a single, scalable solution.

🚀 What’s next for programmable textiles?

Extended Reading of Spacer Fabric Patent Publication: US20240384452A1 Fabric and Methods For Designing and Manufacturing Fabric