A showcase of the flock applicator product line

Design methodology development throughout the brand new 3D manufacturing process.

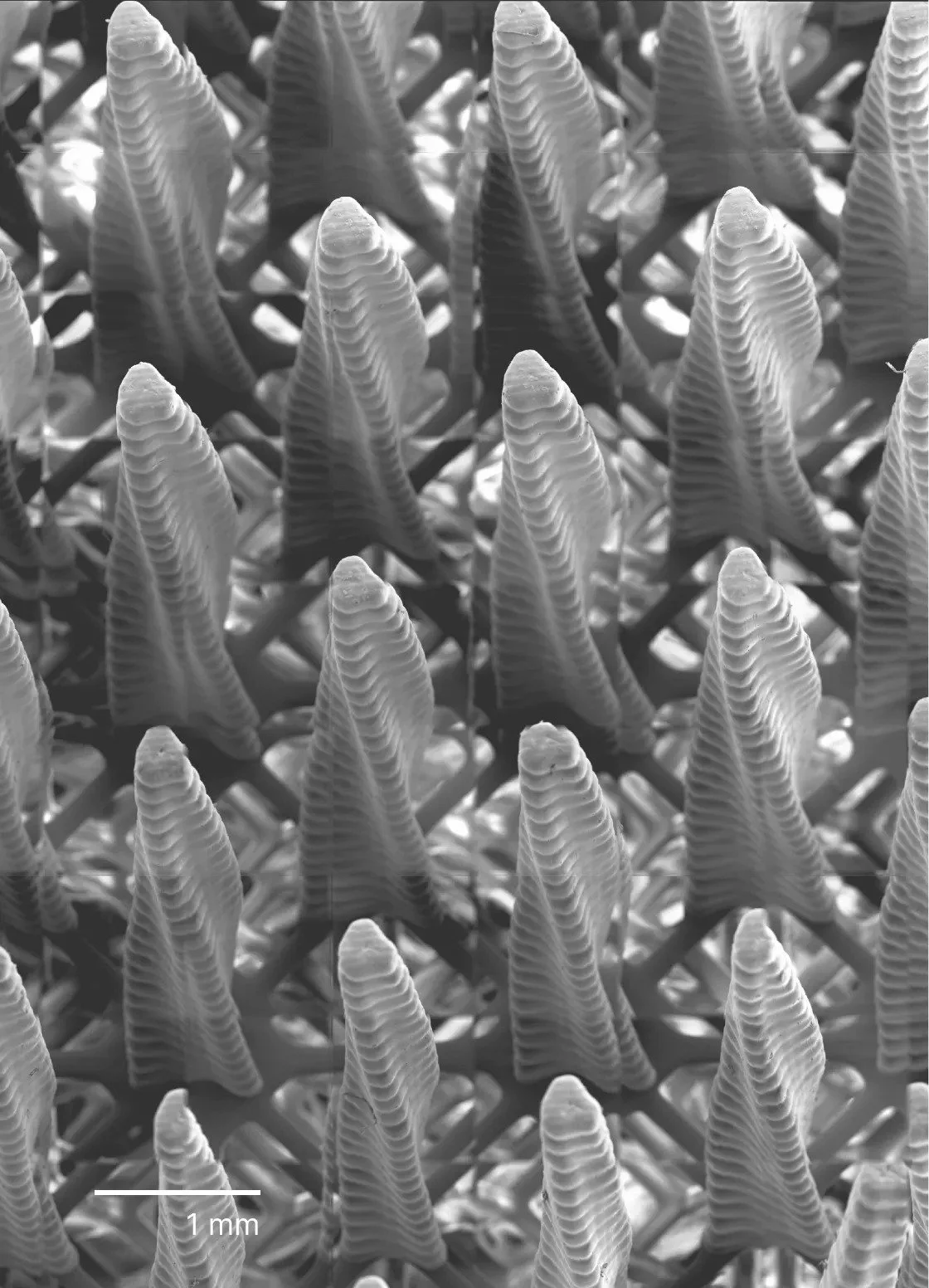

Examples of the geometrical and dimensional potential of the flocking hairs.

The Lumofil brushes were displayed at cosmetic trade shows globally.

Lumofil: Revolutionary 3D-Printed Cosmetic Applicators

2022-2025 OPT INDUSTRIES INC.

Clients: CHANEL, LVMH, Estée Lauder, HCP, GEKA

#NewProductDev #Mascara #MassProduction #FullCustomization #QuickDesignIteration #SelectiveFlocking #DesignValidation

When I first stepped into OPT Industries’ headquarters in Cambridge, MA, in the summer of 2020, I had no idea that I’d be leading a project that would completely redefine how mascara wands are designed and manufactured. At the time, my background in computational design had brought me to this innovative company, where cutting-edge 3D printing technology was already pushing boundaries in medical and industrial applications. What I didn’t expect was that we’d soon find ourselves revolutionizing the beauty industry.

The Beginning: A New Perspective on Mascara Applicators

It all started when I noticed a fascinating overlap between two seemingly unrelated products—medical swabs and cosmetic applicators. Both required high-precision fiber structures designed for optimal material transfer. With OPT’s proprietary 3D printing technology, we could manufacture intricate, highly customizable fiber arrays at a scale that traditional injection molding simply couldn’t achieve. That was when the idea of Lumofil was born—a mascara applicator that could be customized down to the micron level, giving beauty brands an unprecedented level of design flexibility.

Leading the Development of Lumofil

My role in Lumofil wasn’t just about executing a vision—it was about creating one. I led the charge in computational design, taking advantage of OPT’s algorithm-driven printing technology to craft new wand structures that had never been seen before. Traditional mascara wands rely on standardized, often bulky bristle designs that limit their performance. I saw an opportunity to develop brushes with optimized bristle arrangements, precise spacing, and controlled material distribution—all tuned for superior lash separation, volumizing effects, and even product pickup.

One of the most critical aspects of Lumofil’s success has been its ability to outperform even the best mascara applicators currently on the market. The high-precision fiber structures we developed have enabled a better makeup performance, offering smoother application, reduced clumping, and a significant improvement in product pickup efficiency. The full customization capability has proven to be superior to any current design development procedure for cosmetic applicators—allowing brands to fine-tune their mascara wands for specific formulas, target audiences, and beauty trends.

Bridging Prototyping to Mass Production

The transition from a concept to a fully market-ready product is never straightforward, especially in an industry as demanding as beauty. Throughout the development of Lumofil, I worked closely with designers, chemists, and engineers to validate new materials, test next-generation printers, and refine post-processing standards. This was a crucial step in ensuring that our early prototypes could be scaled efficiently into mass production without compromising quality or performance.

This work didn’t just affect Lumofil—it became a pioneering process for product development at OPT Industries. By establishing new standards and best practices, I helped shape the company’s approach to bringing highly customizable, computationally designed products to market. As OPT grew from a seed-round startup to a pre-Series B company, this structured workflow became an integral part of its product development strategy, setting a foundation for future innovation across different applications.

Expanding Global Reach and Protecting Innovation

A major milestone in Lumofil’s journey was securing its intellectual property. Recognizing the uniqueness of our technology, I led the IP development around the project, resulting in two utility patents and nine design patents filed with USPTO and international IP offices. Protecting our innovations has not only solidified OPT’s position in the beauty industry but also created a strong foundation for future advancements in computationally designed cosmetic applicators.

Beyond product development, I also spearheaded the creation of the OPT Cosmetic Sample Box, a curated showcase of our most advanced mascara wand designs. This sample box became a crucial asset in our international marketing efforts, helping us gain exposure at professional trade shows in Paris, New York, and Barcelona. These events were instrumental in introducing Lumofil to the global cosmetics industry, allowing us to engage directly with leading beauty brands and decision-makers shaping the future of cosmetics. Today, Lumofil is trusted by top-tier clients including CHANEL, Estée Lauder, HCP, and GEKA, who are leveraging our technology to push the boundaries of cosmetic applicator design.

A New Era of Beauty Innovation

Seeing Lumofil evolve from an experimental concept to a fully commercialized product has been one of the most rewarding experiences of my career. This project was more than just an exercise in engineering—it was an opportunity to bring real innovation to an industry that has relied on the same manufacturing techniques for decades. Today, Lumofil stands as a testament to the power of computational design and its ability to reshape product development at scale.

For me, this journey has reaffirmed that the best innovations come from unexpected intersections—where technology, design, and creativity meet. Looking ahead, I’m excited to continue pushing the boundaries of what’s possible, not just in beauty, but in any industry where precision and customization can redefine the user experience.

Read more commercial applications on OPT Cosmetics

Read more for the related patent: WO2025076171A1 Additively Manufactured Articles Having A Flock-like Surface