Chevrolet Tracker 2020: Balancing Innovation and Global Platform Efficiency

PATAC Interior Design Team, 2016-2017

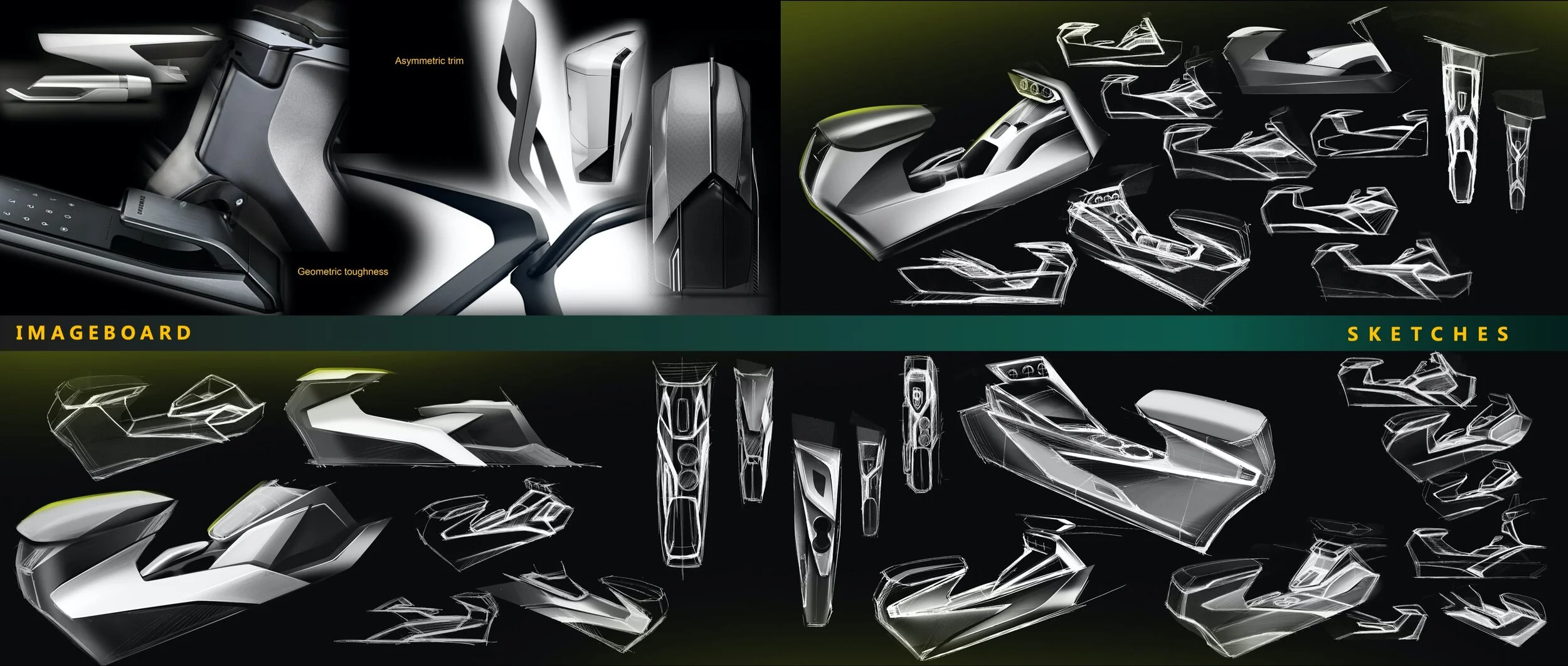

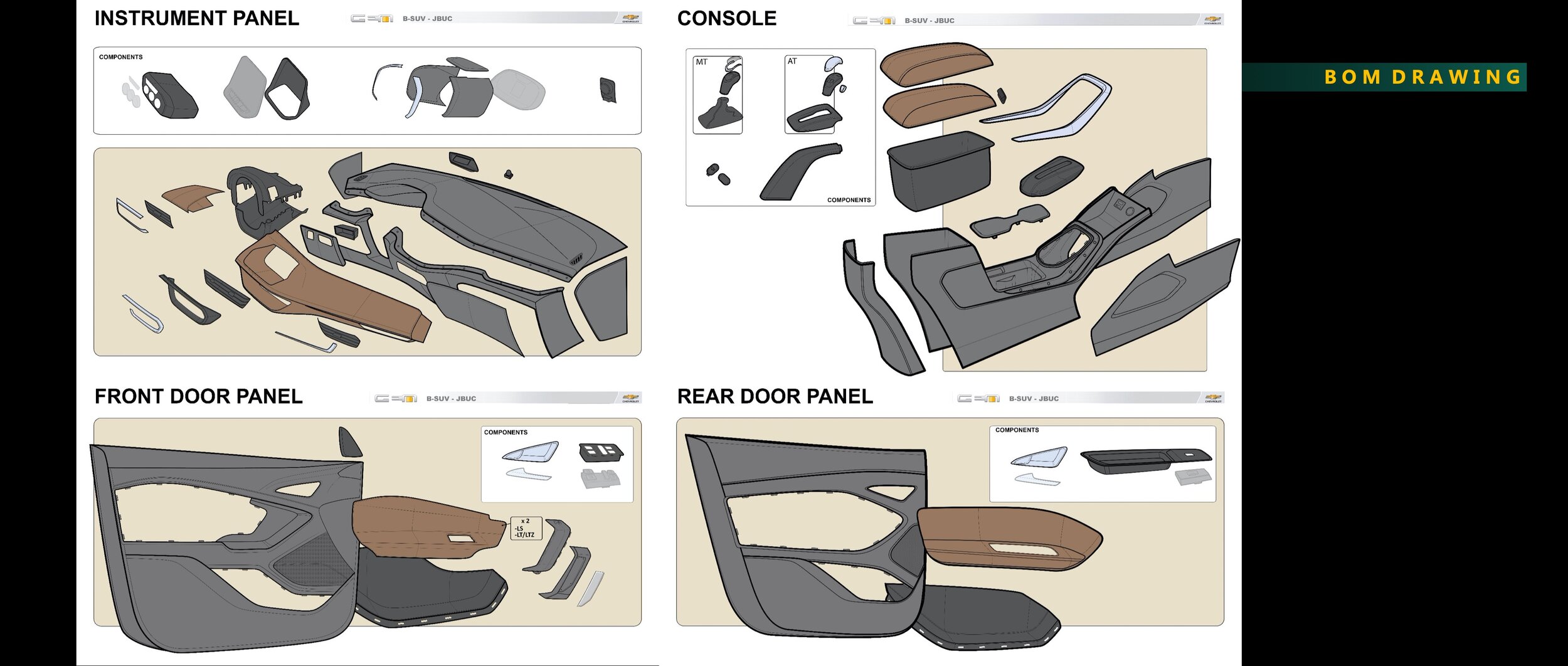

Keywords: Console concept development, Cinema 4D fast form study, XBOM drawing, Engineering input

Designing a Benchmark for Chevrolet’s Next-Generation Compact SUV

In the fast-evolving automotive industry, platform sharing has become a key strategy for maximizing efficiency, cost-effectiveness, and market adaptability. The Chevrolet compact SUV, built on the new JBXX platform, was no exception. The challenge? Creating a refreshed, standout interior design that remained visually distinctive, yet cost-efficient, while maintaining global adaptability across markets.

This project was also a personal milestone—my first interior design collaboration with GM Brazil's design team, where we worked across design, engineering, marketing, and digital modeling teams to bring the console concept to life. The goal was clear: develop a console that offers a unique user experience while maximizing shared-use components to optimize production costs.

The Challenge: Innovation Within Constraints

The console design had to strike a fine balance between style, cost, and engineering feasibility. Unlike a ground-up bespoke interior, this project required:

✅ A unique, market-tailored design that still felt fresh and premium.

✅ Maximum part-sharing across GM’s global platform to reduce manufacturing complexity.

✅ Minimal cost breakdown to keep the SUV competitive in various global markets.

✅ Seamless integration with engineering and digital modeling teams for a smooth execution process.

This required fast design iterations, precise negotiation between teams, and strategic compromises to ensure the final product hit the “golden balance” between design appeal and production feasibility.

Fast-Paced Concept Development & Execution

To keep up with the rapid development cycle, we relied on:

1️⃣ Cinema 4D for Fast Form Studies

Used Cinema 4D for early-stage conceptualization, allowing quick 3D form explorations before committing to detailed CAD modeling.

This approach accelerated design validation, enabling rapid adjustments based on engineering and marketing feedback.

2️⃣ XBOM Drawings & Engineering Integration

XBOM (Extended Bill of Materials) drawings played a crucial role in tracking component usage, cost distribution, and production feasibility.

By collaborating closely with engineering teams, we ensured that design remained feasible within GM’s global platform constraints.

3️⃣ Cross-Team Negotiations & Rapid Iterations

Frequent discussions between design, engineering, and marketing ensured that each design proposal balanced aesthetics, functionality, and production cost.

Agility was key—every iteration required compromises without sacrificing the overall design integrity.

The Golden Balance: Where Style Meets Feasibility

What made this project particularly exciting was finding the perfect middle ground—a console design that was:

✅ Visually appealing with a strong Chevrolet identity.

✅ Cost-effective through smart material choices and platform-sharing efficiencies.

✅ Globally adaptable, allowing different markets to add unique styling elements with minimal tooling adjustments.

From Sketch to Market: Chevrolet’s Compact SUV Launches in 2020

After countless iterations, refinements, and cross-team collaborations, the Chevrolet compact SUV featuring our console design was successfully launched in 2020. The final product was not only a competitive benchmark in its segment but also a testament to the power of collaborative global design execution.

By merging design creativity with engineering and cost realities, this project proved that great design isn’t just about aesthetics—it’s about smart problem-solving.